The Challenge

A leading pet supply retailer needed to expand distribution. Already stocking around 13,000 SKUs ranging from pet food and leashes to cat litter, the number of products were growing and space was quickly becoming an issue. The retailer distributes to over 1,500 storefronts and to customers directly through online shopping.

With several warehouses to date, two distribution centers were well located. One in the southern region and another that that was centrally located. The later distribution center underwent an expansion to supply downstream storage locations. However, with an increasing product line, the retailer needed a change in material handling operations to accommodate both additional SKUs and multi-channel distribution.

The Solution

SSI SCHAEFER was employed as the general contractor for implementation of both the material flow and system design as well as equipping a 13,000 m2 (140,000 sq. ft.) system complex. The equipment includes a 10-aisle pallet narrow-aisle warehouse, a 3-aisle miniload for replenishment supply, and a 4-aisle picking miniload, pallet and bin conveying system, 38 workstations, which 12 are in the preparation area and 26 are in the picking area as well as 60,000 bins.

SSI SCHAEFER implemented a system for mainly automated logitics processes, but incorporated a store-friendly picking and provisioning work flow. Both capacity and efficiency increased--especially in the small product section, which accounts for 50% of the inventory.

The Outcome

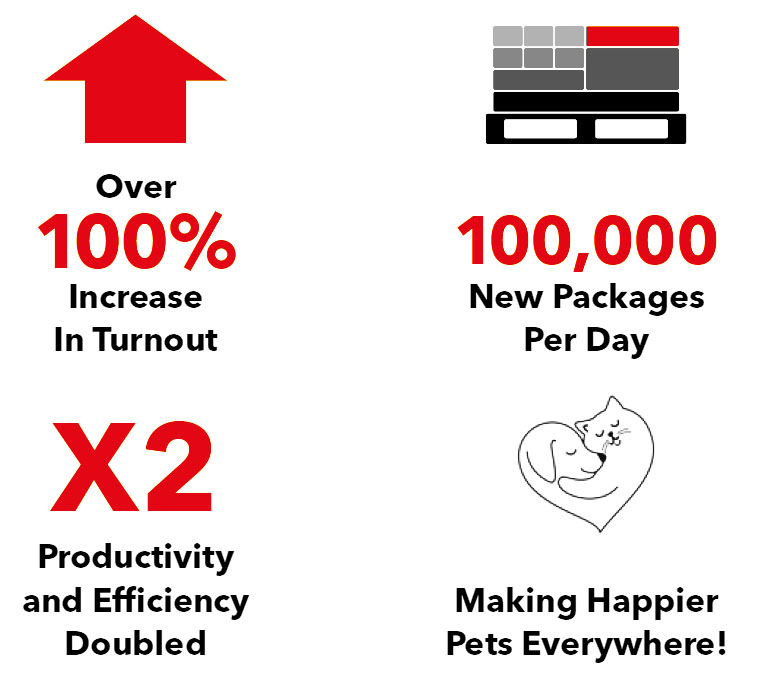

The solution concept with an intelligent linked system for merging and buffering the multi-step order picking process perfectly adhered to all requirements--including structural data, growth targets, process efficiency and expansion options for further growth with the highest throughput capacity. Since installation, over 100,000 new shipments per day in productivity--resulting in happier pets everywhere.

The Details

| Installation

Size |

13,000 m2 / 140,000 sq. ft. |

| Conveying System |

Spiral Conveyor |

| Bespoke design gravity roller conveyor |

| Picking Systems |

4 Aisle pallet and bin miniload |

| 8x SSI Carousel Systems equipped with an Advanced Pick Station two-level |

| Storage Systems |

10 Aisle pallet narrow-aisle warehouse |

| 8x SSI Carousel Systems |

| Rack system with 300 pallet locations |

| 7x SSI SCHAEFER Miniload Crane |

| 3 Aisle Miniload rack system for replenishment |

| 60,000 bins |

| Downstream consolidation buffer containing more than 8,700 storage locations |

| Shipping |

50 Shipping lanes |

| Software Solution |

SSI SCHAEFER WAMAS® Controls Systems |

| Workstations |

38 Workstations |

|

|